It would be rather cost-prohibitive to design, test and manufacture a custom PCB to not only meet the electrical demands, but also the mechanical constraints of every new system. Imagine L-shape and T-shape PCBs as big as some of your household appliances – it’s suddenly quite obvious that creating smaller form factor PCBs has greater efficiency and flexibility while also being environmentally and cash conscious.

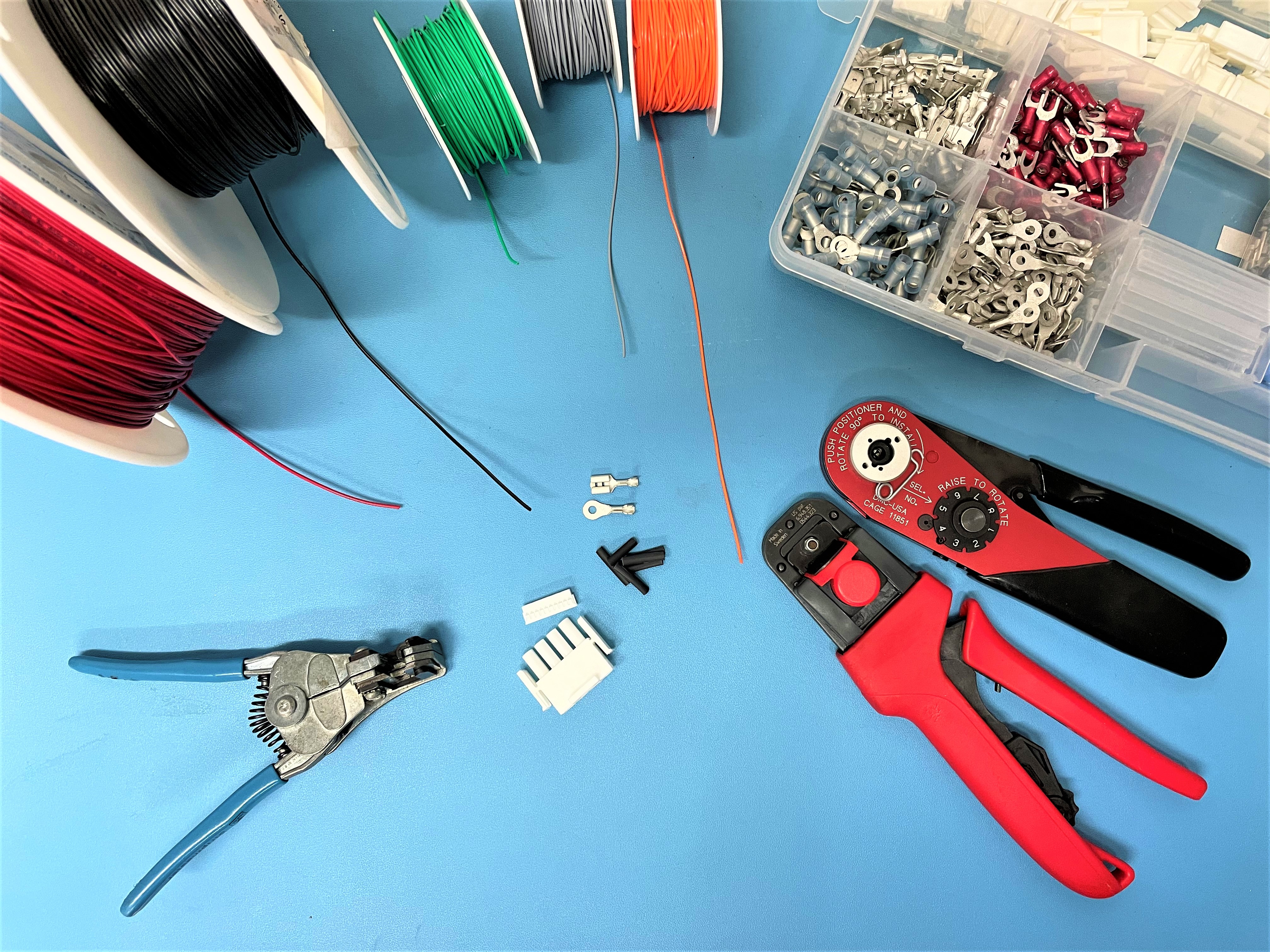

This is where cable assemblies and wiring looms demonstrate their utility as a practical solution. Which, as engineers, we naturally want to try and make the most of in our endeavours. A cable assembly is simply used to connect circuits together.

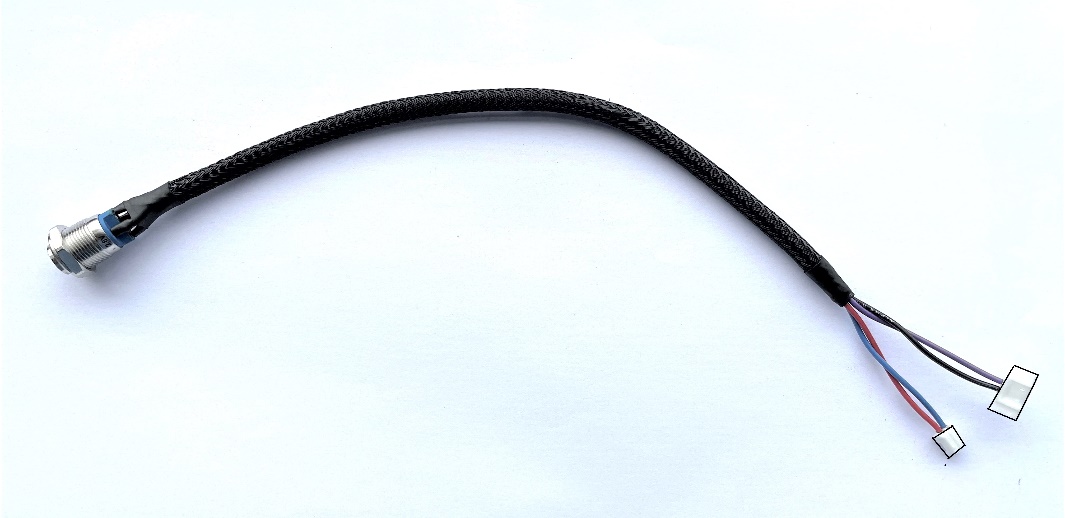

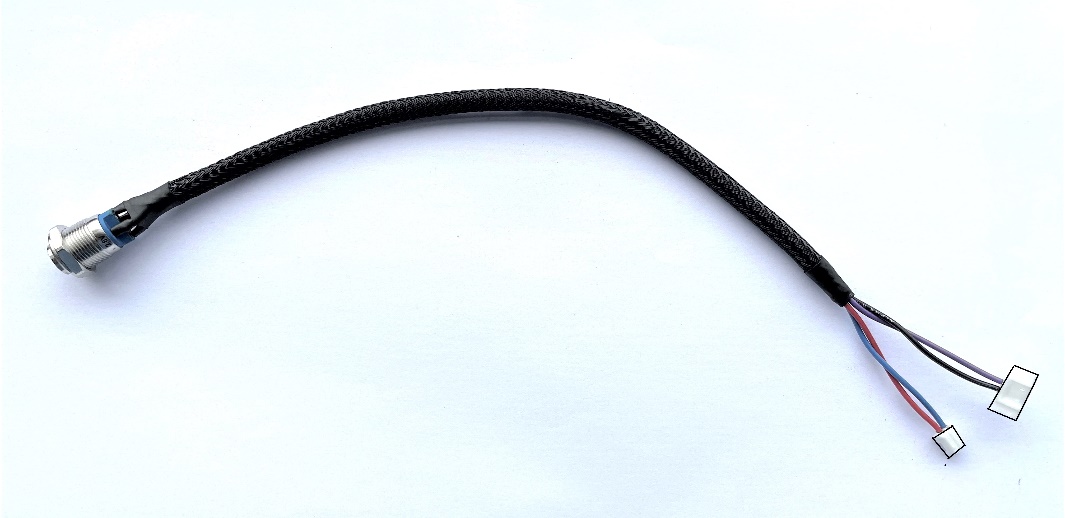

The above is a single-ended wire-to-board pushbutton, terminating from the tabs of the pushbutton which is fastened to the frontplate of our EaglePCs, to a 6-way and a 2-way JST connector housing on a PCB mounted inside the system. As the application this cable is intended for is tight on physical space, soldering the wires to the terminals of the pushbutton and covering the joints with heatshrink is both a neat and practical solution to what would otherwise be a mechanical challenge to ‘create’ system space, had we have chosen to use quick disconnect female terminals.

It’s important that protective measures like heatshrink and protective wrapping are used as they directly extend the lifespan of the parts, which can be cut short by direct damage to the individual wires. It also ensures the quality and reliability of the part itself. What does this cable do? It just powers the system on. Almost every laptop and desktop will have something functioning exactly the same way. You don’t want your only means of powering on a system to be unreliable.

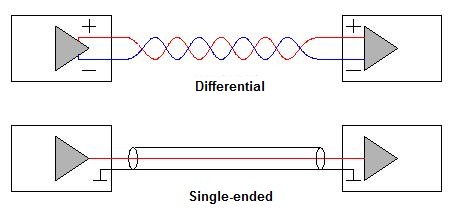

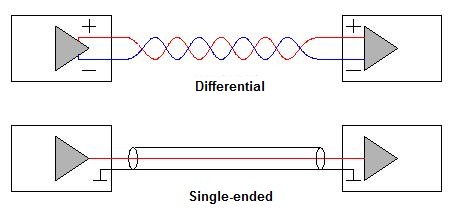

The front panel button cable is an example of a single-ended assembly, which just means that there’s only one positive input and the negative which will be common. However, cable solutions can be far more complex and demanding than a simple pushbutton and we regularly make use of these more complex cables in our daily lives. Network cables/Ethernet cables are an example of differential signalling, where the receiving circuit reacts to the electrical difference between each of the pairs. Using the below illustration helps visualise this distinction between single-ended and differential-ended.

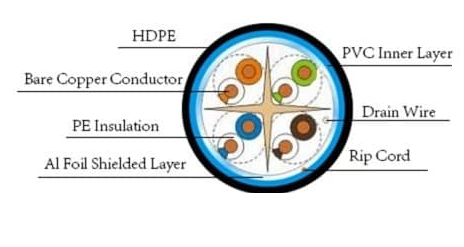

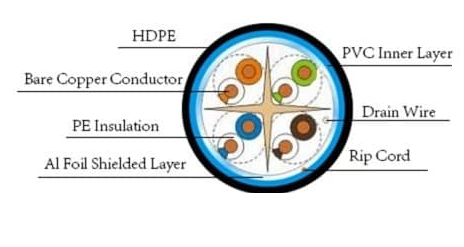

Network cabling is typically 4 pairs / 8 cores with 4 differential-ended signals and, depending on the specification, is capable of up to 600Mhz bandwidth with little crosstalk. As our data acquisition systems use ethernet, a minimum of Cat5e graded network cable terminated to an 8P8C (8 Position, 8 Contact) connector is needed. Higher rated category network cabling implements more means of isolating the pairs from each other, such as individually wrapping pairs with aluminium foil around the wire insulators, adding wire braiding to the layer between the cable jacket and wire insulators, and running a drain wire through the assembly.

The illustration is typical of how Cat6 cable is manufactured and their anatomy. The general requirement differences between the single-ended front panel assembly and a differential-ended ethernet cable is significant. The single-ended just needs to be physically connecting from Point A to Point B, whereas the differential-ended needs to do the same but with a lot more care towards shielding and noise immunity due to the high speed and potential distance the ethernet signals are travelling.

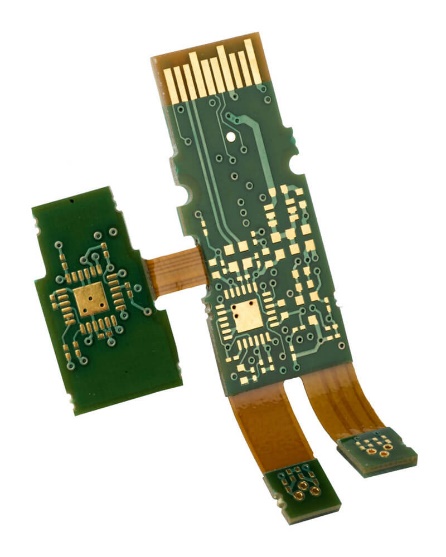

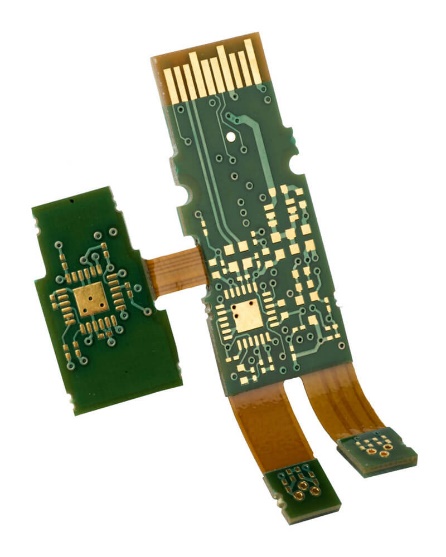

Some manufacturers do away with cable assemblies entirely, opting for a solution using Flex-Rigid PCB’s which build in a flexible substrate on the PCB, which connects to multiple PCB’s and allows the flexibility to position the boards away from one another or on different planes. Flex-Rigid PCBs are only really practical over short distances and are often more costly than cabling solution - but in physically small enclosures can offer elegant solutions to make use of the space available.

The variety and uses of cable assemblies are almost limitless, and the above only scratches the surface of the applications and types of connectivity. It is an important part of the design process to consider how boards, or discrete parts, will interconnect. HGL Systems design complex units with an array of different cabling solutions and would be happy to help overcome any cabling or design problems you are having. If you have a project or requirement for a bespoke cable assembly, please contact us!

Follow Us