Waste, in the Lean Manufacturing context, is any activity that consumes resource but adds no value to the end customer.

The activities that create value for the customer often only make up a small portion of the manufacturing process, which is why reducing or eliminating these wastes is important. It is necessary to understand that in each process there are necessary wastes, such as testing, planning, reporting and quality assurance. However, there are also pure wastes, which do not bring value and can be removed from the process or minimised where possible. Any activities that involve waiting are considered a pure waste.

One method often used to identify the wastes in a manufacturing process is mapping your value stream. Doing so allows you clearly visualise the manufacturing process including both value-adding and wasteful steps. The more details you include in your mapping, the more knowledge you will gain about your process. Doing this task as a team, utilising the knowledge of those carrying out the process, is important, as some wastes are not always obvious from the outside looking in.

Improving processes to eliminate waste is an important step for the success of a company. Having wasteful activities can decrease quality, increase customer costs, lower profits, and can affect employee satisfaction.

The lean manufacturing methodology identifies seven major activities which can contribute waste:

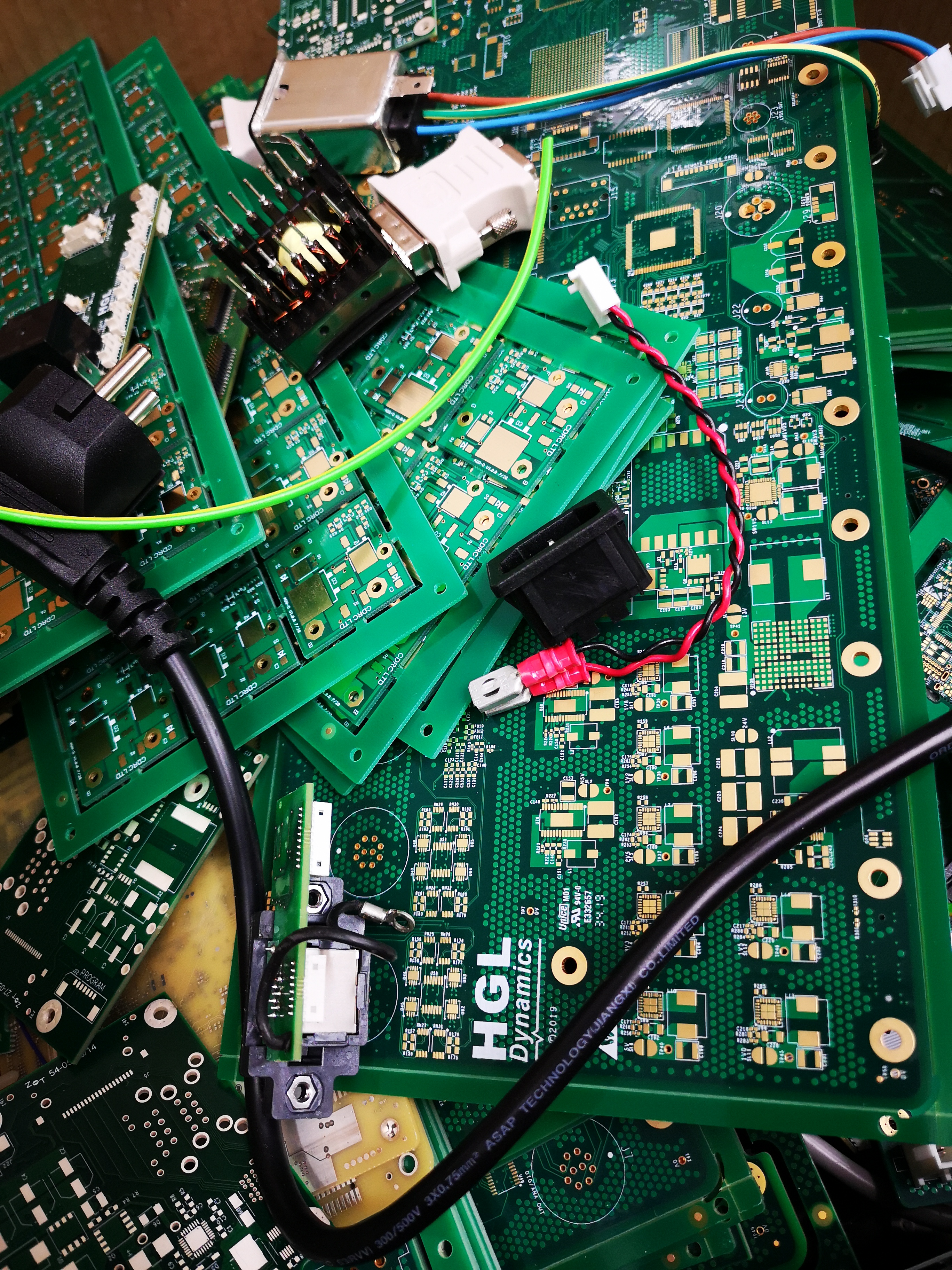

Inventory

A company may hold excessive inventory or work-in-process “just in case”. Companies sometimes overstock to meet unexpected demand, protect from production delays, or deal with poor quality. Excessive inventories do not meet customers’ needs and do not add value, they only increase storage requirements and deprecation costs.

Waiting

Waiting is any idle time produced when two processes are not synchronised. The company pays for the time spent by all employees, including time which is not spent adding value. This is the easiest waste to recognise. Whenever goods or tasks are not moving, the waste of ‘waiting’ occurs. For example, an employee can be kept waiting or working slowly whilst a machine cycles.

Defects

Defect parts can lead to rework or modification and in some cases to scrap. Defective parts requiring rework or remanufacture will cause an increase in labour and more importantly time and can impact the scheduling of other parts through production.

Over Production

Producing more product than needed, or producing the parts too quickly. Excessive amounts of end products or tasks requires additional transportation, more motion, increased waiting times and can impact the manufacturing schedule of other products. Examples of the cause of overproduction are large batch sizes, unreliable processes, working to an inaccurate or volatile forecast.

Motion

This waste can be identified as any movement of a person or machine that does not add value to the product. Ideally an employee should not have to move far to complete their job – all that they need should be at their workstation.

Transportation

Similar to Motion but identified by any movement of the product or parts that does not add value to the product. Subsequent processes should be close together and material should flow directly from process to process to reduce significant delays between processes. Excessive transportation can affect quality as well as create unscheduled delays.

Over-processing

Over-processing is putting more into the product than is valued by the customer. Adding costly features not used by the customer, unnecessarily tight tolerancing or adding expensive finishes to parts not seen by the customer are examples of over-processing.

Follow Us