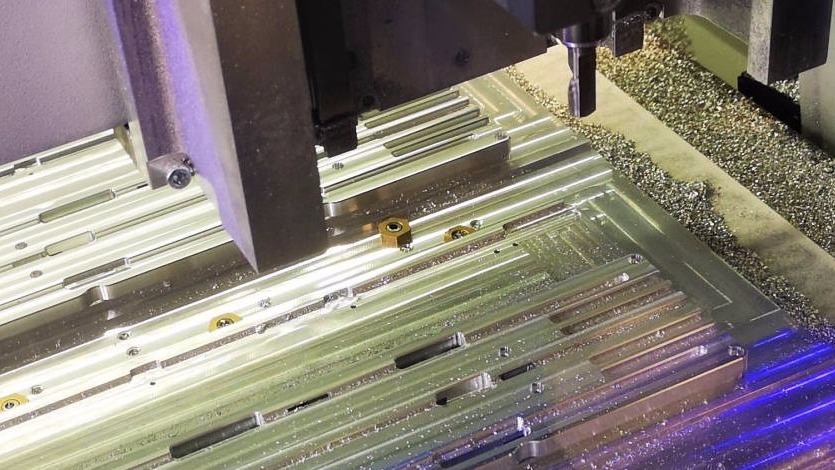

CNC machining and CAD

Most users of these machines create product designs with CAD/CAM software, which enables the tool's movements to be controlled by the computer. Other helpful machining tools, such as drills and lathes, can be computer operated as well. Prototyping using a CNC machine can help to eliminate potential defects that could cause manufacturing issues. This reduces the chance of faulty products being released.

CNC machining or 3D printing?

3D printing is increasingly used to produce prototype products. However, prototype CNC machining offers businesses far greater versatility and a larger range of construction options than 3D printing. Often referred to as an additive process, 3D printing builds up parts by adding material progressively. In contrast, CNC machining creates parts by removing material gradually from a bigger base shape. For this reason, it is classed as a subtractive process.

After a prototype is approved, more expensive methods - such as injection moulding - are normally used to mass produce a product. A prototyping CNC milling machine creates parts with similar mechanical properties to those produced by injection moulding, so you get a more representative and functional prototype than is normally possible with 3D printing. This is a cost effective way of ensuring that the prototype performs in the same manner as the final product. Consequently, unforeseen problems are unlikely to arise when the final piece is made.

Prototype production quality

CNC machining rapid prototyping produces surface finishes of exceptional quality. This compares favourably with 3D printing, which often causes layer lines to appear. Based on the post-processing methods used and the chosen material, parts that are CNC machined can be powder-coated, anodized, bead blasted, chrome plated, or sanded with different grits to create a shiny surface. Another advantage of CNC machined prototypes is that they can be made from materials that are too costly to use with other prototyping techniques. Even prototypes made from common materials, such as aluminium, are cheaper to produce with CNC machining than they are with 3D printing.

Project turnaround times

Based on the CNC machining prototype service used and the intricacy of the prototype model, CNC machines can offer amazingly fast turnaround times. Once the computer has received the necessary data, it can use the machinery without much human input. Once a part is produced, no further details have to be added to the computer to create further items - because it has the file saved already. Increasingly sophisticated CNC software and machinery, like our 3-axis CNC machines, have made the process suitable for small volume projects and rapid prototyping.

Tell us about your project goals

If you’d like to find out more about how CNC machining can streamline and improve your prototyping process, get in touch with HGL today. Our design engineers at HGL Systems can complete technically challenging projects to strict deadlines. We can work flexibly to suit your needs and achieve your project goals. If you want to create a prototype for a new product you are developing, contact us today to learn more about the benefits of CNC machining.

Follow Us