What is Three-Axis Machining?

Traditionally, rotary milling relied on a human production line operator directly putting each metal piece through a short instruction set. Material is cut away, filed, and drilled to a written template.

Manual machining was time-consuming, expensive, tedious, and prone to human error. Thankfully, advances in computer numerical control (or CNC) allowed a series of automatic, programmable cutters, drills and tools to revolutionise production – improving both speed and accuracy.

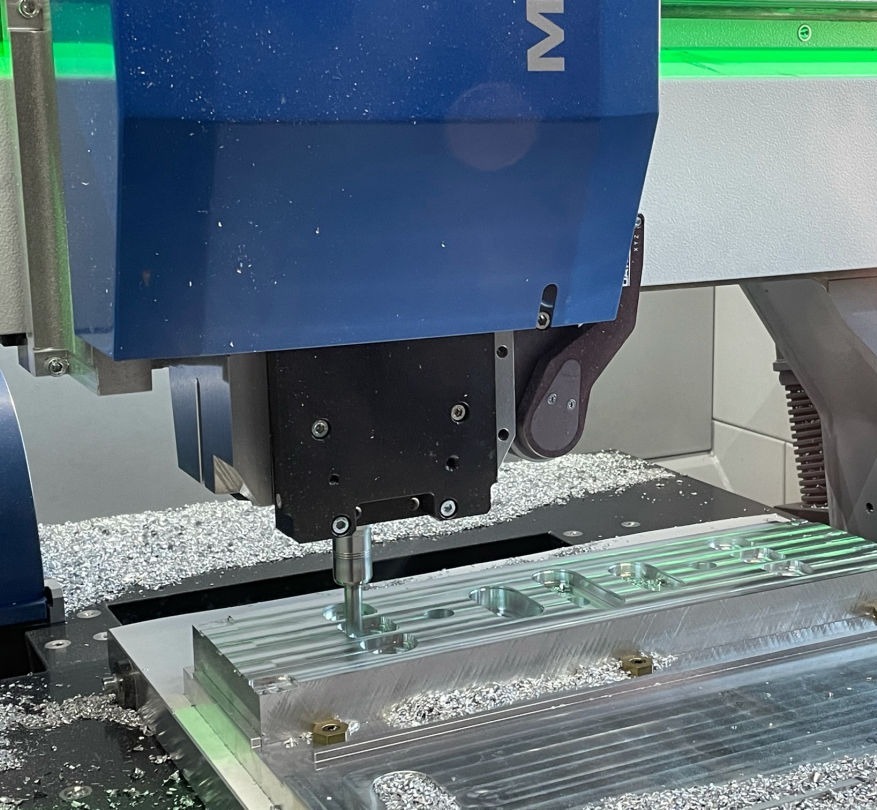

The three-axis, automated milling machine first emerged in the 1950s. A static Z-axis (base) clamp kept the metal in place while a single cutter completed a computer-controlled path of movements along the vertical ('Y') and horizontal ('X') axes to create shapes, grooves, and cuts (hence 'three axes').

Modern Advances

Today's three-axis milling machines are a lot more capable and sophisticated than their punch-card controlled predecessors. New innovations include automatic tool and bit changers, carousel part loaders, fast-switch clamps, cooling jets, and safety enclosures for multi-stage machine arrays, while CAD software allows electronics designs to be fed directly to the CNC machine from a computer or tablet.

Multi-Axis CNC Alternatives

Sometimes, three-axis control isn't enough for what designers and operators want to do. Highly intricate parts, for example, often need extremely precise levels of tooling to meet the required engineering standards.

Four-axis control adds in a rotational 'A' axis to the 'X'-extender, allowing for the rotary mill to move position and create subtle gradients while in use. Five-axis (and up) machines add a 'B' axis to 'Y', giving truly superb levels of control to all moving parts. Both can easily match and surpass thermoplastic 3D printing quality.

Next Steps

At HGL Systems, we have two highly precise CNC machines and years of experience using CAD technologies to design and assemble small batch parts for clients in a range of industries. To request a quote or to find out more, please call or email us.

Follow Us