Component Kitting

We can process components supplied by the customer or source components according to your bill of materials. We can also advise alternatives which may be more cost-effective or readily available.

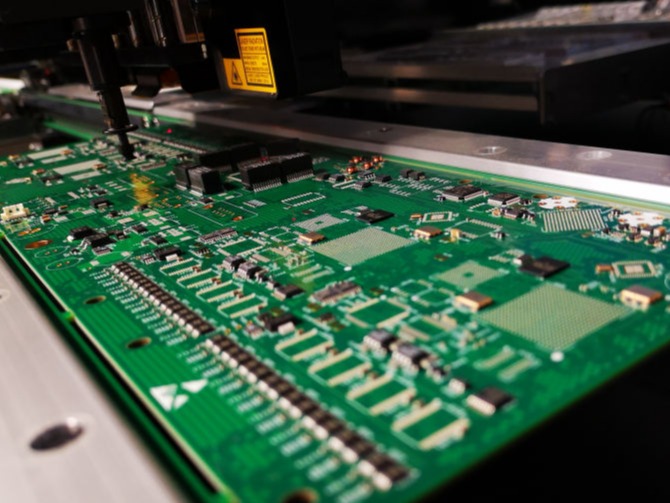

Assembly

Our investment in state-of-the-art equipment allows us to efficiently assemble your PCBs whether the requirement is for a one-off prototype or a production batch.

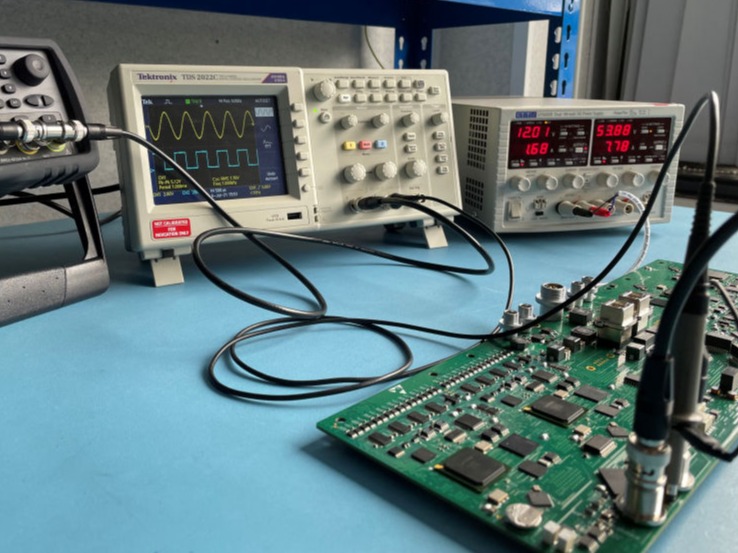

Inspection and Test

All of your boards will be inspected by an IPC-certified inspector. We pride ourselves on quality and are constantly looking at ways to improve. We hold JEDEC 001 accreditation.

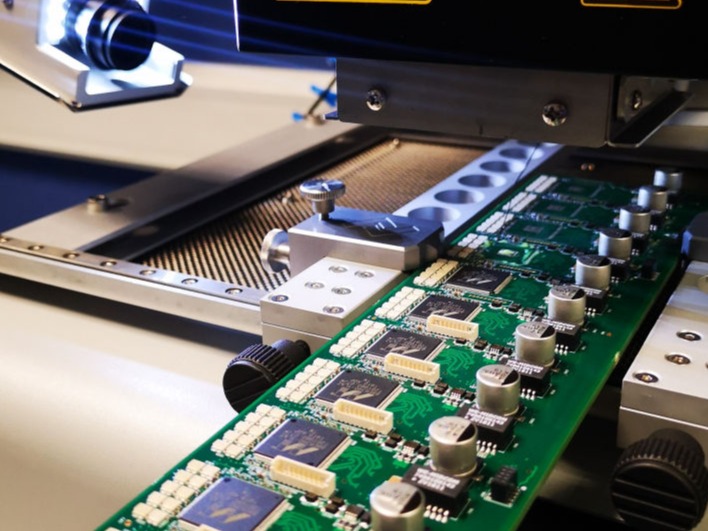

Rework

HGL have invested in an Ersa HR 550 System with desoldering, placement and soldering capabilities of all types of surface mounted devices up to 70 x 70 mm.